On paper, Li-CO2 batteries could boast far superior energy density to today’s state-of-the-art battery types – but this nascent technology requires further analysis and development, writes May Chan

Lithium-CO2 (Li-CO2) batteries are a relatively new type of battery that uses CO2 as the cathode and lithium as the anode to generate electrical energy. Compared to traditional batteries, Li-CO2 batteries could prove more sustainable and eco-friendly: for example, while traditional batteries rely on rare and toxic materials, Li-CO2 batteries use CO2 as their primary material, which is non-toxic, easy to procure and relatively easy to recover and recycle.

Most importantly, perhaps, Li-CO2 batteries have a high energy density, which makes them an ideal choice for applications where space is limited, such as inside electric vehicles or small craft engine rooms.

The technology is attracting interest from various sectors. For example, researchers at the University of Illinois, Chicago (UIC) have been studying the potential use of Li-CO2 batteries for applications such as electric vehicles and grid storage, and have developed a new type of cathode material that, they claim, can improve the battery’s energy efficiency and cycle life.

The UIC team believes that Li-CO2 batteries could come to deliver an energy density more than seven times that of current, state-of-the-art batteries. In other words, while today’s batteries can produce 256Wh per kg, Li-CO2 batteries could theoretically deliver 1,876Wh per kg. As such, Li-CO2 batteries would be able to hold more than seven times more energy, or be produced more than seven times lighter, than their conventional counterparts. The UIC researchers add that their prototype Li-CO2 battery has managed 500 consecutive charge and discharge cycles.

Optimisation studies

UIC is not alone in this respect: a number of research institutions and companies are actively working on the development of Li-CO2 batteries, including The Toyota Research Institute, Massachusetts Institute of Technology and the University of Waterloo, Canada. Several Korean institutes – including Gyeongsang National University, Pohang University of Science and Technology (POSTECH) and Korea Research Institute of Chemical Technology (KRICT) – are also conducting research in this field.

Some of this work has involved optimisation of the cathode’s properties (such as surface area and porosity) to increase the amount of CO2 that can react with lithium ions. Additionally, researchers are keen to explore ways in which various catalysts – the materials that accelerate chemical reactions – can be used to improve the performance of Li-CO2 batteries. It’s believed, for instance, that catalysts such as metal nanoparticles or carbon nanotubes could improve the battery’s energy efficiency and lifespan.

Similar optimisation studies are being conducted into the electrolyte that separates the cathode and anode inside the battery. By changing the electrolyte’s composition or adding certain additives, researchers may be able to improve the battery’s energy efficiency and cycle life. Solid-state electrolytes, which can conduct ions like lithium without the need for a liquid or gel-like electrolyte, are also under investigation.

Several drawbacks

This research is necessary as Li-CO2 battery technology is still its infancy, and several drawbacks have already been identified. One is that Li-CO2 batteries may have a limited cycle life, meaning they can only be charged and discharged a certain number of times before their performance starts to degrade. This is mainly because solid carbonate forms on the surface of the cathode during discharge, which can lead to irreversible damage over time.

Another possible drawback is that the reaction between lithium and CO2 produces a lot of heat, which can lead to energy losses unless managed properly. Li-CO2 batteries also have slow charge and discharge rates, which can limit their usefulness in applications that require rapid energy delivery.

There is also cost to consider: the current cost of Li-CO2 batteries is relatively high due to the complex materials and manufacturing processes required to produce them at present.

Further, Li-CO2 batteries come with their own safety concerns, one being the potential for release of CO2 gas during operation. Leaked CO2 can be hazardous in high concentrations, potentially causing headaches, convulsions and death. Li-CO2 batteries also operate at a voltage of around 4v, compared to 3.6v for traditional Li-ion batteries, and this higher voltage may lead to a greater risk of thermal runaway.

“Obvious potential”

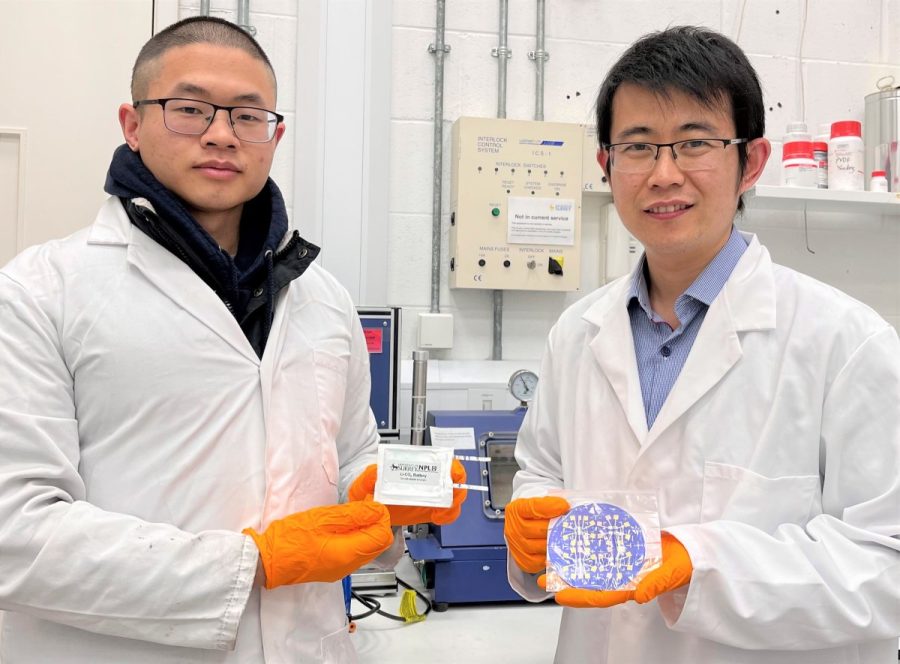

There has been some progress of late. In 2022, a UK collaboration between the University of Surrey, the National Physical Laboratory and chemicals company Johnson Matthey announced that it had developed a Li-CO2 battery with a theoretical energy density of 1,800Wh per kg: extremely close to the estimate reported by the UIC researchers. These particular Li-CO2 batteries would be manufactured as valve-controlled, sealed ‘pouch cells’, designed to address the potential problem of electrolyte leakage and evaporation.

According to University of Surrey project lead Dr Yunlong Zhao: “While our Li-CO2 battery technology has the obvious potential to be used in next generation electric vehicles, we also believe that this technology could be used in future intermittent power generation systems – for example, to store wind energy.”

So, could Li-CO2 batteries come to replace Li-ion batteries in the marine sector? Their higher energy density means they could store more energy for the same weight or volume, which could be especially useful for maritime applications where space and weight are at a premium, such as in the small boat sector. However, it’s important to stress that Li-CO2 batteries are still very much in the development phase, and must overcome the aforementioned technical challenges before they can be commercialised. The technology, though, holds promise.