By Jose Gonzalez and Guntars Zommers Stolt Tankers, The Netherlands

Biofouling is a major contributor to energy efficiency reduction; the ships spend almost their entire operational life afloat favoring the creation of biological layers (biofilm) and macrofouling populations in different working areas of the ship. The consequence of this occurrence is mainly reflected in additional dragging, losses of thermal performance of facilities, economic losses, inability to carry out proper maintenance practices.

The new regulations and decarbonisation goals promulged by IMO are forcing all marine stakeholders to find a suitable solution to decrease vessels’ environmental footprint. There is a wide range of options that can be tested/applied; this paper presents the early results of the experience gained with one of them i.e., the application of graphene coating to a propeller of a ship aiming to decrease the fouling rate.

Graphene is a relatively new material given it was only isolated in 2004; its potential for application in the shipping industry was therefore not studied and highlighted until the launch of the Global Marine Technology Trends 2030 report (GMTT 2030). That report identified the exceptional combination of strength and toughness of metals that can be achieved by nanoprecipitation, such as doping nano-sized carbide or copper precipitates; and the graphene’s antibacterial properties will create new opportunities for application in fields like hull coating. Using graphene films, hull surfaces will be covered, avoiding micro- and macro-fouling attachments. The robustness and resistance of graphene are useful characteristics for this type of application.

Biofouling and Graphene

Fouling refers to the formation of deposits on equipment surfaces which significantly diminishes both equipment performance and its operational lifetime. One of the fouling types is biological fouling – biofouling – which refers to the settlement and growth of microorganisms (biofilm) and macro organisms such as mussels, oysters, barnacles, etc.

The creation of complex structures called extracellular polymeric substances (EPS), in which the microorganisms are embedded, facilitates the development of specific microbial communities. As such, the hull of the ship is constantly colonised both by micro and macrofouling in several different locations, including the rudder and seachest. This fouling results in significant efficiency losses linked to, among others, the vessel’s speed, fuel consumption increase, drag and leads to increased cleaning operations, equipment maintenance and associated docking time.

To give one example, the US Navy studied hull fouling’s economic impact on a medium-size combat ship, an Arleigh-Burke class destroyer, which found severe associated costs related to extra fuel consumption and the hull cleaning routines. The losses due to the hull cleaning and reapplication of coating are fewer than those caused by extra fuel consumption. Across the entire Arleigh-Burke Class fleet the costs were estimated at some US$56 million per year.

A further example of biofouling impact is the decrease in heat transfer efficiency; it has been identified that the impact of microfouling is causing opex losses associated with the heat exchanger-condensers, consequently increasing the fuel bill and emissions footprint. The mitigation of microfouling in heat exchangers used in marine applications will significantly improve the efficiency of the whole propulsion package installed onboard. No surprise therefore that biofouling has been identified as an area with major potential in achieving the emission reduction targets for 2030 and 2050.

In this context, graphene is a material of growing interest to the shipping community, given its remarkable physical properties and the potential it offers for future applications. Graphene’s anti-bacterial properties might create new opportunities for in fields like the coating of hull–propeller–niche areas. Utilising graphene films, it’s conceivable that hull surfaces might be covered, thereby avoiding micro- and macro-fouling attachments.

Although scientists were aware that one atom thick, two-dimensional crystal graphene existed, until recently no one had worked out how to extract it from graphite. In the early 20th century, some physicists even argued that strictly 2D crystals were thermodynamically unstable and could not exist. Finally, two researchers at The University of Manchester, Professor Andre Geim and Professor Kostya Novoselov, became the first to isolate a layer of graphene using ordinary scotch tape and graphite. This method, known as mechanical exfoliation, saw them awarded the 2010 Nobel Prize in Physics for the discovery of graphene and its characterisation.

From the main characteristics of graphene, several important properties can be derived, some of these being both unique and extreme. These include linear energy dispersion, as the standard sequence of the conductivity with the magnetic field observed with the conventional Quantum Hall Effect (QHE) appears to be shifted in graphene. In the field-effect configuration, this implies that carriers can be tuned continuously between holes and electrons by supplying the requisite gate, something that implies a wide range of mechanical, optical, and thermal attributes.

Graphene represents a very promising material for multiple applications not only in marine but also in other industrial applications, for instance, power generation, automotive, and communications.

Stolt Acer

Stolt Acer. Source: Stolt Tankers

This article presents one of the potential multiple applications graphene may have for shipping in the shape of an ultra-low friction coating applied to the propeller of a chemical tanker, the first instance of such a coating.

The subject vessel, Stolt Acer is a chemical parcel tanker belonging to Stolt Tankers fleet as part of its Asian fleet. It was built in 2004 by Kitanihon Shipbuilding in Hachinohe, Japan, and fitted with 28 tanks able to carry as many different cargoes at the same time. The vessel is powered by a two-stroke engine able to deliver 7,980 kW at 120 rpm and equipped with three generators able to deliver a combined output of 1,950 kWe.

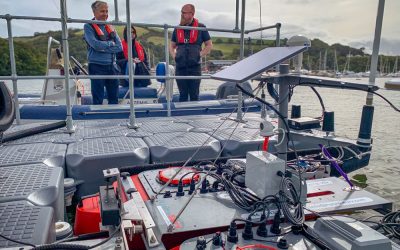

Immediately before drydocking, the hull and propeller sequence of events was as follows; on 14 March 2021 a hull cleaning and propeller polishing service were carried out, it was followed by another hull cleaning and propeller polishing on the 17 February 2022. Two months later, on 6 April 2022, the vessel arrived at the Gryfia Shipyard in Szczecin, Poland, for a scheduled Hull treatment drydocking. The antifouling (AF) coating system applied during this docking was supplied by Jotun Paints and consisted of a combination of SeaQuantum Classic S (applied to the Vertical Sides) and SeaForce 60M (applied to the flatbottom).

The diameter of the Stolt Acer’s is 5.5 m having an area of 14.73 m2. The paint applied was XGIT PropPrimer (l layer) plus XGIT Prop (1 layer), which is an ultra-low friction hard foul release system combined with a special primer that adheres well to bronze or similar alloys.

Graphene plays an important role in creating the strength that increases resistance to cavitation and the low friction that provides propeller thrust efficiency. In preparation for the coating application, the ship’s propeller was grit blasted to SSPC-SP-5 standards, assuring the abrasive mixture was of sufficient size to secure and anchor the profile before receiving the new coating.

Graphene coating applied to Stolt Acer’s propeller

Both layers were applied using the spray method. When applying these layers for the first time, a trial must be conducted before spraying and all the humidity and external conditions checked to ensure a proper application and final thickness result implementation in the propeller. Additionally all surfaces must be clean and dry, with any trace of oil and grease removed. The ship can be re-floated (or propeller submerged) 48 to 72 hours after the final coating application, depending on the outside environment temperature.

Data analysis was undertaken both by Stolt Tankers and the coating manufacturer, but the results presented here are those carried out by Stolt Tankers. Analysis was based on noon report data received from Stolt Acer and a comparison of consumption before and after application.

Before drydocking the excess consumption value for Stolt Acer was 1.33 metric tons of fuel per day, whereas after drydocking a value of -2.27 metric tons of fuel per day was recorded, in other words an improvement of 3.6 metric tons of fuel per day. With regard to performance speed, before drydocking Stolt Acer achieved 11.97 knots, while after drydocking the value recorded was 12.49 knots, a difference of 0.52 knots. The difference before and after drydocking of the consumption performance in percentage is 20.3 %.

Taking into consideration a hull maintenance impact of circa 12-15%, due to heavy fouling condition on arrival to drydocking, propeller maintenance impact is between 5-7% and most importantly with no change in efficiency over time. A potential saving of 3-4% due to graphene coating was therefore confirmed by the data analysis.

The results are very promising, albeit not definitive at the time this article was submitted. Nevertheless, Stolt Tankers has pioneered a potential option for decarbonisation and improving our emissions and sustainability goals.

Acknowledgments

Stolt Acer crew; John Agustino (Stolt Acer Superintendent); Valentins Baburgs (Stolt Tankers Asia Fleet Manager); Maren Schroeder (Stolt Tankers Managing Director); Stolt Tankers Energy Conservation Team; Tobias Gröeger (Storm Geo); Marciel Gaier (GIT Inc.); Tim Kent (Lloyd’s Register of Shipping); Professor Fai Cheng (Lloyd’s Register of Shipping).

This article is an adaptation of a paper originally presented at RINA’s ‘Scaling Decarbonisation Solutions – Reducing Emissions by 2030’ conference in Rotterdam, The Netherlands, 29 November-1 December 2022.