Classification society ABS says that more work is needed to better understand the effects of air lubrication systems (ALS) on the underwater radiated noise (URN) generated by a vessel.

In recent years ALS manufacturers, such as industry leader Silverstream, have been keen to promote the URN-reducing benefits of ALS in addition to their energy saving potential. Last year, a study by the University of Southampton, sponsored by the International Chamber of Shipping, suggested that ALS could help reduce vessel noise by more than 10dB.

“The general understanding is that the microbubble air lubrication has the potential to attenuate the URN [and] create a speed of sound mismatch between the bubble curtain and the surrounding water,” ABS tells TNA.

“One of the main assumptions behind this understanding is that the air bubble curtain can be maintained to such an extent that effective sound impedance can be formed around the main noise sources. This can be challenging as the main noise sources (propeller and machinery) are typically located near the aft body, while existing designs of air lubrication systems do not intend to maintain the air bubble curtain near the aft body, let alone beyond the vessel length.”

Because bubbly water could reduce propulsion efficiency the air bubble curtain coverage for ALS typically avoids getting close to the propeller, which is one of the primary sources of ship URN. Another thing not fully understood is the URN that’s generated by the ALS itself. While the components – pumps, compressors and air injectors – will increase URN, the magnitude is small compared to the propeller and other onboard machinery. However, this would increase relative to the overall URN when the propeller is operating at lower speeds.

More uncertain is the noise generated by the actual bubbles. ABS explains: “One of the main sources of URN from ships comes from the collapse of cavities formed by vapourised water due to local low pressures on a rotating propeller. The injected microbubbles or air layers are believed to behave differently than propeller cavitation, and their burst in water and pulsation may not generate loud broadband radiated noise.”

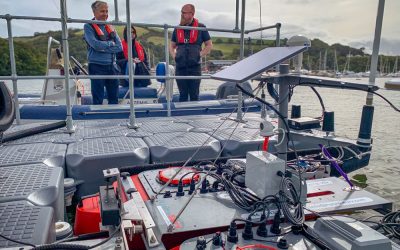

ALS are designed with the intention of maintaining the integrity of an air layer underneath the vessel bottom, minimising the opportunity for those bubbles to escape and the air layer collapse. The best way to confirm this would be through a dedicated sea trial measurement of a vessel equipped with ALS, however this falls outside the remit of class Type Approval of a system, which is primarily concerned with safety factors, such as the potential of the air bubble layer to compromise the manoeuvring and stability of a ship (although no such incidents have been reported at this time).

Although it will clearly impact upon a vessel’s EEDI/EEXI and CII ratings, determining the energy saving potential of an ALS is likewise not a requirement for type approval, although ABS does offer this as an additional commercial service for interested parties. Nevertheless, ABS comments that more recent ALS are using markedly less energy during operation than earlier models by the same providers.

One of the challenges in improving understanding of the energy-saving potential of ALS is the complexity in developing accurate numerical simulations. ABS comments: “The current IACS Rec. 173 guideline on using CFD for EEXI excludes coverage on using CFD for air lubrication. However, progress has been made in recent years in numerical modelling of the frictional drag reduction [and] validation against sea trials and model tests has shown a promising trend. Further validation of the modelling approach for each specific type of ALS is still needed.”

Large flat bottom vessels are far better suited for air bubble technology, while vessels operating in deeper drafts require a higher head pressure and therefore more energy for the compressed air. In the case of LNG carriers, container ships and cruise vessels, ABS notes that there is a critical draft/speed range that should be evaluated during sea trials.

No two ALS systems are the same and ABS advises shipowners to contact the equipment provider to determine whether the performance characteristics – meaning the net propulsion power savings – will suit the ship type and its operating profile.

Thanks to Qing Yu, ABS, director, technology, and Lefteris Karaminas, ABS, manager, sustainability, for their cooperation with this article.