Combination carrier operator’s CLEANBU project helps it post record-breaking profits

To an earlier generation the combination, or ore-bulk-oil (OBO), carrier was seen as the ideal ‘everyman’ vessel; capable of switching between dry and wet cargo depending on marketing fluctuations, or switching between cargoes on reverse voyages rather than an unprofitable return journey in ballast. But they were difficult to maintain, particularly if switching between carrying oil and a ‘clean’ dry cargo such as grain.

Although a spate of OBO accidents, such as the sinkings of the Berge Istra (1975), its sister Berge Vanga (1979), the infamous MV Derbyshire (1980) and its sister Kowloon Bridge (1986) did raise safety concerns about their durability and stability, they remained a popular choice until the early part of this century. However, many ended up trading in a single commodity, in part because it was difficult to put the contractual arrangements in place to make the exercise worthwhile.

Smaller combination carriers continued to be deployed on inland waterways, notably by Russian operator Volgotanker, but for a time it even seemed their role in transoceanic transportation could be passing. Among the few to keep faith in the concept was Norwegian shipowner and operator Torvald Klaveness. Between 2001 and 2007 it took delivery of five caustic bulker (CABU) combination carriers, intended to transport caustic soda on one leg and various dry bulk products on their return. Three further ‘Mark II’ CABUs followed in 2016-17.

But Klaveness had bolder ambitions and in 2013 began exploring the feasibility of a next-generation combination carrier concept, the CLEANBU. In 2018, having raised capital and placed orders for the first vessels in the series, Klaveness Combination Carriers (KCC) was established as a separate entity and listed on the Oslo Stock Exchange.

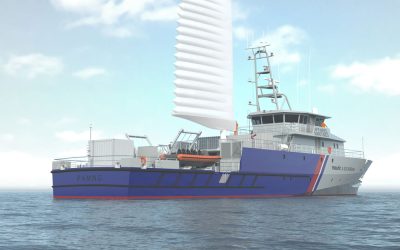

The first CLEANBU vessel, MV Baru, was completed by China’s New Yangzi Shipyard in January 2019, with seven more following by 2021. Boasting 40% lower CO2 emissions per ton mile transported cargo compared to standard vessels, the 83,500dwt CLEANBU is classed as an LR1 tanker in wet mode and a Kamsamax when dry. Notably it has no centerline bulkhead, depending upon class-approved filling restrictions to maintain stability, with stricter self-imposed limits to bolster those safety margins.

The CLEANBU alternates between wet and dry modes on a continuous basis after each voyage, cleaning and isolating the cargo handling systems before loading. It is specifically designed to ensure that all areas of the hold and their surfaces are easily cleanable, with ample freshwater, eating and wastewater capacities. Since there is no standard for combination carriers, meaning that Klaveness has effectively had to create its own best practices, such as 360° pictures of the tanks after cleaning, allowing for virtual inspections. KCC says that the feasibility of drone inspections and AI-based cleanliness evaluations are also being explored

By the company’s own admission the CLEANBU project has been hard work. Notwithstanding the teething problems that arise with any new design, even after entering service, persuading charterers to embrace the new concept took some time, particularly those looking to transport oil products. Indeed it wasn’t until the start of last year that there was sufficient acceptance to achieve good operational efficiency of the fleet. Since then, charterer confidence has grown further, with KCC reporting record-breaking profits last year.

A notable landmark in that progress was the three-year contract of affreightment (COA) signed with Brazilian company Raizen, which produces sugarcane-based biofuels, signed in early 2023. Raizen’s requirements to transport liquid and dry produce in opposite directions between South America and India made KCC’s ships uniquely attractive for this task.

Inevitably, with the growing cost of regulatory compliance and eventually zero or low-carbon fuels adding further to operating costs, KCC is leaning heavily into its sustainable credentials. In February, the company announced it had secured an A- rating for its efforts to tackle climate change as part of the annual CDP disclosure, placing it in the ‘leadership’ band of companies.

Meanwhile, KCC has also announced plans for a zero-emission-ready CABU III series of vessels for delivery in 2026, which the company says will achieve a 45% reduction in carbon intensity and intended to capitalise on an anticipated increase in caustic soda imports to Australia (where it is a key component in bauxite refining). The first of these new vessels is expected to be delivered in 2026.