More than half a year into the inaugural data reporting for IMO’s carbon intensity indicator (CII) many shipowners still seem a little uncertain exactly what the new regulations will mean for them, according to Japanese classification society ClassNK.

“We tried to arrange interviews with the shipowners but most didn’t take it seriously because the company next door doesn’t do anything,” says Hiroshi Shibako, general manager of ClassNK’s technical solutions and marine GHG certification departments. “Maybe the time will come when they start to rush and take it seriously, perhaps when the operator suddenly requests their fuel consumption. But at the moment it’s only the front-runners.”

Historically class societies have taken a back seat with regard to the economics of shipping, but decarbonisation has muddied the waters. Fuel consumption, or more specifically the need to reduce it – and thereby not only costs but emissions – demands new insight.

That’s particularly true of CII, which sets a rising bar with regard to compliance. A vessel that attains an acceptable rating today could within a few years find itself slipping towards the undesirable E rating without remedial action to curb its carbon emissions.

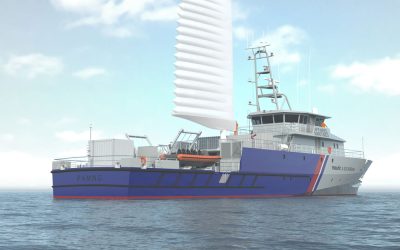

Equally the cost of doing so might be so prohibitive the only viable option is scrapping the ship. While energy saving devices such as wind-assisted propulsion or propeller boss caps have gained some traction the far more popular choices remain engine power limitation and voyage optimisation.

To help owners develop a better understanding of GHG emissions for not only individual vessels but their entire fleet, last year ClassNK launched its Zero Emission Transition Accelerator (ZETA) tool. Linked to the pre-existing ClassNK MRV Portal – a support tool for MRV IMO-DCS and EU-MRV – ZETA visualises CO2 emissions and simulates CII ratings based on fuel consumption data. Currently some 5,000 ships operated by 2,000 different companies are already using the service.

“Not only ClassK but also ships using other class societies can use our service,” explains Shibako. “We want to expand this service to as many of our clients as possible.”

Beyond its use providing the CII rating for individual vessels, ZETA is also a benchmarking tool since anonymised data is also openly accessible. Although available as a free service, ClassNK is also interfacing and augmenting it with data from other providers. In one recent example, ClassNK’s Finnish subsidiary NAPA wished to integrate the ZETA data with its own commercial voyage optimisation solution to provide owners with performance data.

Ammonia ascending?

Given the Japanese government’s strategy to transition towards a hydrogen-based economy in the coming decades it’s understandably that ClassNK anticipates ammonia and hydrogen are the leading candidates among alternative fuels. Shibako notes that much depends on the success of the new engine technologies being developed by the likes of MAN, Wärtsilä and some Japanese engine makers, which should come to fruition within the next two years. By 2030 it is anticipated that a trend towards hydrogen-fuelled engines will begin in earnest.

For its part ClassNK, keen that the guidelines it previously published for ammonia, methanol and LPG inform the ongoing development of industry-wide guidelines at IMO, a process which commenced the eighth session of the Carriage of Cargoes and Containers subcommittee (CCC8) last September. “Once IMO establishes reliable guidelines we will feed back into our own guidelines, which will then be fixed as class rules. Then we can use this rule to provide feedback to designers.”

Perhaps not surprisingly though a growing number of ClassNK’s clients are attracted by the nascent potential in carbon capture and storage (CCS) technologies that might negate any need for a switch from conventional fuel. In April, it published its ‘Guidelines for Shipboard CO2 Capture and Storage Systems’, which incorporates experience gained from ClassNK’s involvement with the Carbon Capture on the Ocean (CC-Ocean) project, the first time a marine-based CO2 capture system was used on an actual voyage.

“We are happy because a CO2 capture manufacturer has already started to use our guidelines. They recently made a presentation and introduction of their product referring to them,” says Shibako. However, while cautiously optimistic he is concerned that the additional power required to run CCS equipment, not to mention the significant onboard space required to accommodate it, is likely to prove prohibitive for the foreseeable future.