The global shipping fleet must adopt low- and zero-emission fuels to meet the climate goals set by IMO, writes Tore Stensvold. The goal is a 20% reduction in total GHG emissions by 2030, and a 70% reduction by 2040, both relative to 2008 levels, with the end goal of achieving net-zero emissions by 2050.

Ammonia and hydrogen are seen as two likely and possible fuel options. However, the properties of ammonia and hydrogen fuels introduce safety risks related to toxicity and flammability.

In March, DNV issued the whitepaper Safe introduction of alternative fuels – focus on ammonia and hydrogen as ship fuels. Linda Hammer, principal engineer at DNV Maritime, and one of the authors of the whitepaper, tells The Naval Architect that the paper was issued to support and assist shipowners who want to use the fuels before the IMO regulations are in place.

“IMO is working on developing regulations, but it is a long process,” says Hammer. “IMO has issued interim rules for ammonia and will proceed with interim rules for hydrogen. It will take many years before they are mandatory.” She explains that it is still possible to get ships approved with alternative fuels, but the process is more burdensome and time-consuming. One must use the risk-based approval process known as the alternative design approval (ADA) process and the regulatory framework for alternative fuels through the International Code of Safety for Ships Using Gases or Other Low-Flashpoint Fuels (IGF Code).

Hammer says that the exact requirements for the approval process may vary from case to case, depending on the flag administration’s acceptance of available interim guidelines and classification rules as their approval basis, and on factors relating to the design and its maturity.

DNV has aimed to develop ammonia and hydrogen classification rules with prescriptive requirements as far as possible, acknowledging that this will ensure increased predictability for owners, designers, and shipyards. “DNV issued class rules for ammonia in 2021 and for hydrogen in 2024,” Hammer continues. “If the flag administration agrees, those rules can be applied. It is very important that those who are building early contact the flag state to clarify the approval processes and scope – and whether they can use the classification rules.”

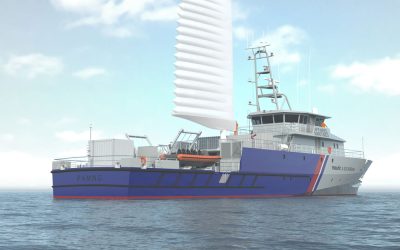

So far, only a couple of tugboats and one deep-sea vessel, Fortescue’s Green Pioneer, have been converted and use ammonia as the primary fuel in a dual-fuel engine. “Fortescue used the ADA process,” says Hammer. “We are also working with Eidesvik on the conversion of the [94.9m] platform supply vessel Viking Energy to ammonia operation, using our class rules for onboard installations and equipment.”

Of the global fleet of around 60,000 ships over 1,000gt, 20% account for about 80% of emissions, according to DNV’s Maritime Forecast 2024. This means the most significant impact will come from measures applied to the 12,000 largest ships. Currently, 98.8% of these ships use combustion engines that burn some form of heavy oil or marine distillates.

“It is extremely important that shipyards and suppliers are involved in the design phase,” says Hammer. “Technical safety barriers and safety margins must be incorporated into the plans as soon as the first drawings are available.” Equally important is that the crew knows how to handle the fuels, is aware of the risks and understands the system well to maintain and operate it. DNV recently issued a competence standard for those operating ships that will use ammonia as fuel.

“It’s not enough to build the ships and equipment safely if the crew doesn’t know how to handle and operate it and what to do in a given situation,” says Hammer. “We have extensive knowledge of ammonia-handling because it is shipped as a commodity on large gas carriers. Ammonia is also used as a refrigerant in refrigerated ships and fishing vessels.”