The offshore wind business is growing rapidly as more companies seek to make investments in the sector. This has created numerous opportunities for manufacturers to supply equipment.

Latest among these is Swedish-Swiss owned multinational ABB, which has received an order for a comprehensive package of equipment for two new vessels.

The large wind turbine installation vessels (WTIVs) are being built for Havfram, a company specialising in offshore installations. Both will be capable of installing offshore wind turbines with a rotor diameter of more than 300m. They will feature a crane that has a lifting capacity of 3,250tons. This will allow them to carry XXL monopiles weighing up to 3,000tons for installation in water depths of up to 70m. The two NG20000X-HF WTIVs will be built in China by CIMC Raffles Offshore Ltd, one of China’s largest shipbuilders.

Havfram has significantly expanded its offshore wind capabilities in recent years and is in the process of expanding its fleet in order to provide vessel capacity from 2026 onwards. The company is owned by Sandbrook Capital, an investment firm with a strong green portfolio.

Other companies have also begun their own WTIVs projects. Both Kongsberg Maritime and Maersk Supply are both involved in the production of new designs. In 2022 Kongsberg Maritime signed a contract of €28 million with Chinese shipbuilder COSCO Shipping Offshore for an F-class foundation installation vessel. This will be delivered to Danish service provider Cadeler in 2025.

ABB has a previous track record supplying equipment for WTIVs. In 2021 the company secured an order to outfit two vessels for Monaco-based Eneti with an advanced package of systems. Both vessels will be able to install the next generation of turbines offshore at depths of up to 65m, and will feature a battery installation from ABB.

The new vessels on order represent a significant upgrade on this with the ability to carry much heavier loads and to install turbines at much greater depths. deck load and the extreme lift heights expected over the next decade.

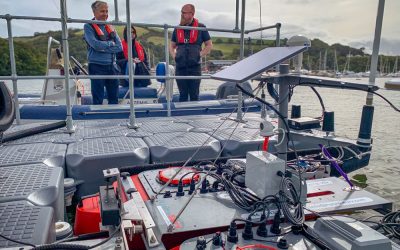

They will also both utilise four Azipod electric main propulsion units with a total propulsion power of 17 MW; the Onboard DC Grid power distribution system and a 4.1MWh energy storage installation. The two vessels will also feature ABB’s Ability Marine Pilot Control with Dynamic Positioning System for advanced vessel control.

“The performance of our Wind Turbine Installation Vessels will be pivotal in meeting the needs of the offshore wind market today and tomorrow. To ensure superior performance, we chose the broad scope of ABB power, control, propulsion and automation technology, complemented by the through-life support from ABB’s remote diagnostics and global service capabilities,” said Even Larsen, CEO Havfram Wind, in a statement.

Analysis by classification agency DNV indicates that by 2050 offshore wind will provide as much energy as oil and gas. In 2020, offshore wind generation grew by almost 30 percent, with capacity additions of 6 GW, according to the International Energy Agency (IEA). In its ‘Net Zero by 2050’ roadmap, the IEA predicts that the offshore wind sector will need to grow by 80 GW each year for the world to achieve net zero by middle of the century.