SeaTec Services reports increased demand for its propeller polishing and hull cleaning services on the back of the latest IMO environmental regulations

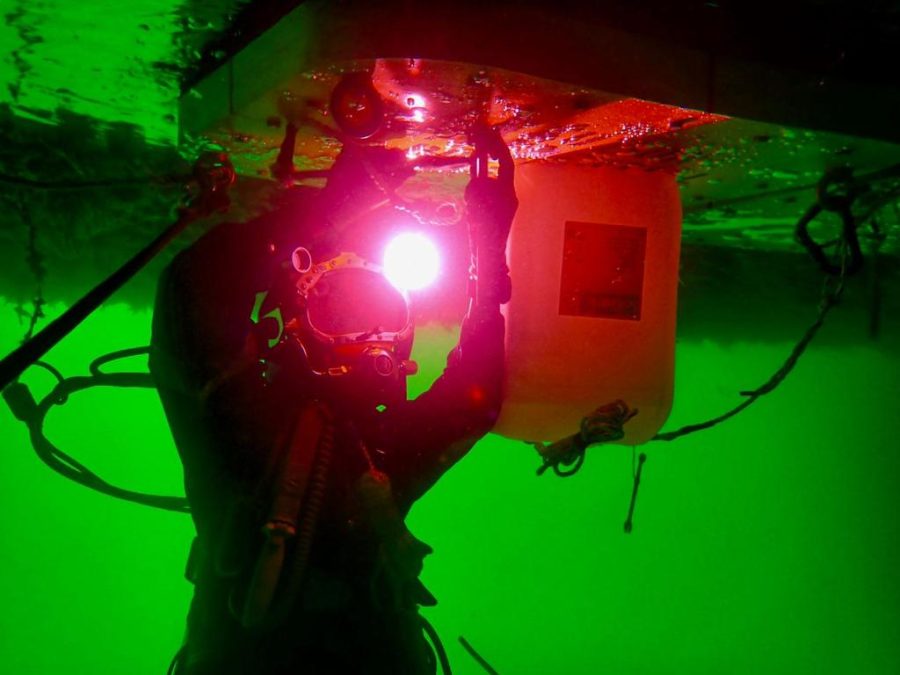

UK-based SeaTec Services last year launched its new closed-circuit propeller polishing system, which features technology that captures biofouling and metal particles and removes them safely to the surface for filtering. Over the past year the company has rolled this technology out within the UK and Northern Europe initially and has received a positive reception within the market, particularly from shipowners looking to comply favourably with the new Carbon Intensity Indicator (CII) rules. Testing has also now been carried out to confirm compliance with BIMCO guidelines, offering additional reassurance, and there are now plans to roll out the solution on a global basis.

Nick Laker, managing director, says, “It is still the case that many ports around the world have banned propeller polishing and hull cleaning due to the adverse environmental impact these activities can have. However, we have seen over the past year that closed circuit propeller polishing and hull cleaning has the capability to gradually reopen ports, like Southampton in the UK, which had previously stopped this type of work.”

SeaTec now has partnerships in place with a range of suppliers who offer closed circuit ROV hull cleaning, including Ecosubsea. The deployment of ROVs in combination with SeaTec’s closed circuit propeller polishing system means that hull cleaning and propeller polishing can now be carried out even in the most strictly regulated ports, the company claims.

CII measures how efficiently a vessel transports goods or passengers and the first reporting of an individual ship’s CII is due no later than 31st March 2024. Vessels will receive a rating of A (major superior), B (minor superior), C (moderate), D (minor inferior) or E (inferior performance level). The rating thresholds will become increasingly stringent towards 2030 and a vessel rated D for three consecutive years, or rated as E, will need to develop a plan of corrective actions.

The implementation of CII is therefore focusing shipowners minds on the benefits of propeller polishing and hull cleaning on a regular basis, as this can significantly reduce fouling and thereby cut fuel consumption and carbon emissions. Laker says, “Last year we saw a strong uptick in activity for our underwater cleaning and maintenance teams and the positive market trends were to a large extent driven by the industry requirement to comply with CII. We are getting a lot more enquiries about hull and propeller cleaning, with companies keen to get more information about the benefits, as well as where they can have hull and propeller cleaning work carried out.”

Undoubtedly also the high profile and well documented case of the cruise ship Viking Orion, which was refused permission to enter Australian ports in January this year, due to hull fouling, until the vessel had its hull cleaned by divers outside of Australian waters, has pushed the issue up the agenda. “The case highlighted the danger of allowing hull fouling to build up and we are now increasingly being called upon to provide advice and technical support to ensure vessel can enter Australian ports without delays in future, “ says Laker.

As a result of the combination of such factors, SeaTec reports that 2023 has started with higher levels of demand for both hull cleaning and propeller polishing services. Laker observes, “It has certainly proved to be timely to educate customers about the benefits and the fact that cleaning the hull and propeller of some vessels can reduce fuel consumption by 10-15%. Moreover, we can reassure them that, if they do this work, it will ensure that most ships will achieve a CII score of A or B and thereby demonstrate that they are operating in an environmentally efficient manner.”

Blanks manufactured in SeaTec’s workshop ready for shipping to customers. The containerised system is said to be particularly popular for offshore vessels

Growth in demand is being seen right across the commercial vessel sector, Laker adds, as well as in the offshore market, with several projects undertaken on submersible drilling rigs, for example. Laker adds, “We are also carrying out more bio-management surveys to keep owners informed about the condition of the underwater hulls of their ships.”

Based on the successful initial roll out of its closed-circuit propeller polishing and hull cleaning service, SeaTec is now in discussions with several European ports currently closed to such work, including Zeebrugge. Laker says he hopes that agreements will be reached with the key Belgian port over the coming months, and certainly before the end of 2023. This follows on from the decision of the port of Rotterdam to only open its water to propeller polishing and hull cleaning with closed-circuit capture system.

Laker observes, “We are seeing a clear trend for ports to open up to closed-circuit, but not open circuit type systems. That puts us in a very strong position to meet shipowners needs to have this work done in locations of their choosing as they strive to achieve the CII ratings they are aiming for.”