In California, pilotage for vessels sized 750gt and over is mandatory, so the San Francisco Bar Pilots (SFBP) must accompany nearly 8,000 ships in and out of the state’s ports each year, writes Stevie Knight. The pilot vessels are required by law to stand ‘on station’ outside the Golden Gate Bridge, roughly 12nm away from the SFBP pilot station, for six days at a time. It’s a challenging ocean environment, featuring occasional 6m seas with 10-second wave periods.

That puts pressure on the SFBP and its boats. “They need to go out in almost all weathers to keep the port open, but still be safe for pilot transfers,” says Jeff Rider, senior marine engineer for naval architect Glosten. They also need to be able to increase their pace to 15knots to catch the big ships, and to accommodate eight pilots along with four crew, so they cannot adopt a more compact design.

Over the past 20 years, the SFBP has been pleased with its three, almost identical 32m pilot vessels P/V San Francisco, P/V California and P/V Drake. However, last year the game changed around the California Air Resources Board’s (CARB’s) new rules for harbour craft. As reported in Ship & Boat International March/April 2024 (page 24), the new rules mandate cleaner engines and the use of diesel particulate filters (DPFs) on existing vessels.

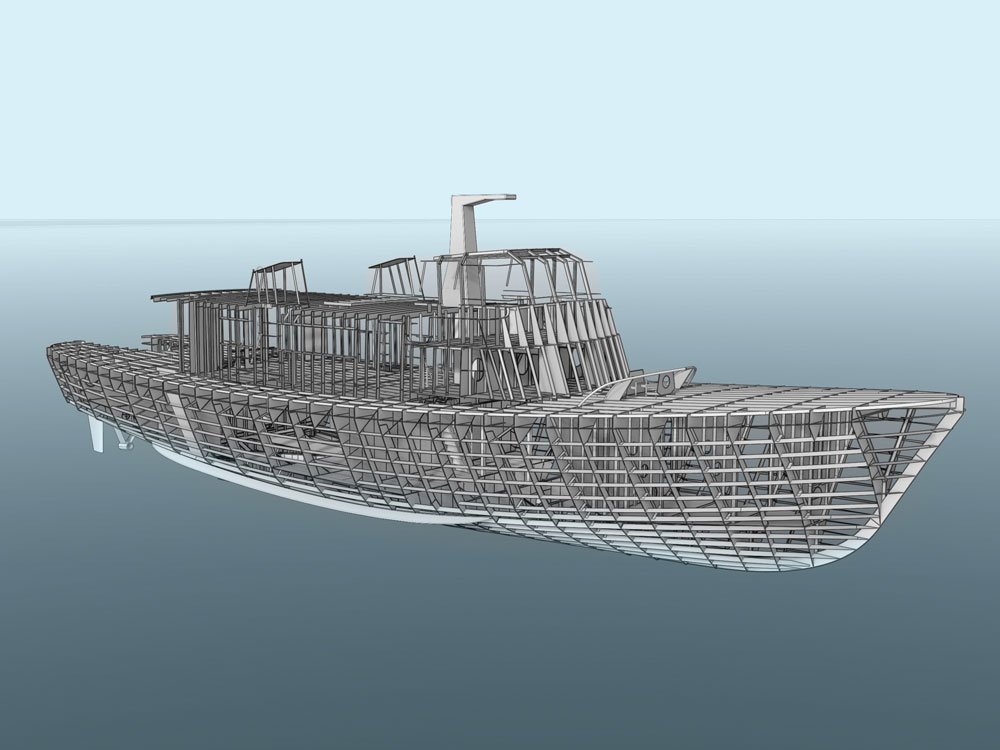

The SFBP knew it would be a tough call for a refit strategy: the CARB-mandated after-treatment technology and DPFs wouldn’t fit their boats’ original footprint and would increase each boat’s weight. Therefore, a new design had to replicate the originals as far as possible while keeping within the 200tonne limitation, which has implications for crewing. So, the team lengthened the new design by 1.8m to 33.5m while retaining both beam (8.5m) and draught (2.7m).

One of the big wins from this extra volume was the creation of enough space for batteries, enabling a hybrid configuration. “These boats loiter a lot of the time because, if you drift, you’re bobbing all over the place,” says Rider. “So instead, they keep their bow into the weather – that maintains a more acceptable motion for pilots on board, and especially for the crew during rest hours.” Glosten settled on a 271kWh energy storage installation, configured on a DC distribution, to provide the design with a couple of knots loitering on battery power. The batteries are either charged at berth or via a PTO/PTI on the gearbox behind the main MAN 882kW engines, which have a compact SCR after-treatment system. The batteries take over and drive the five-bladed propeller at very low speeds, allowing the crew to shut off the main engines. The PTO/PTI also allows the gensets to provide propulsion power to supplement the batteries.

Rider remarks: “The design is pretty different from the original, but we’ve tried to maintain the aesthetic – so the layout is roughly the same.” The main deck has a large superstructure holding the galley and lounge, with a raised wheelhouse sitting above an anti-roll ‘U’ tank. Below deck, the pilot rest area is located forward of the engine room, while the crew have staterooms aft. He adds: “It was an interesting puzzle to figure out where the battery rooms made sense; where all of the after-treatment kit needed to be placed; and to be sure that everything fit. But we also spent a lot of time looking at draught, weight and trim. In general, motion gets better with additional length, but we were particularly concerned about acceleration at the pilot boarding location itself because that’s far forward of the vessel’s centre of gravity.”

As a result, the design called for repositioning some of the supply tanks to the area below and forward of the engine room. Those for the SCR are in the aft ‘wings’ nearby, while the fuel tanks are outboard of the staterooms.

When it comes to making the new boat design liveable, there were also concerns about noise and vibration levels. So, the entire engine and gear system are installed on a resiliently mounted frame, while damping tiles have been laid on certain sections of the hull. Also, various layers of insulation and floating floors have been laid under the entire lounge area.

The first two station boats are expected to be in service by the end of 2024, with the third due to enter service by the end of 2025.