Methanol has several known benefits as a marine fuel, including the significant reduction in NOx, SOx and particulate matter emissions when burned, compared to traditional HFO/MGO. Producers can also create ‘green’ methanol through renewable sources and ‘blue’ methanol through carbon capture and storage.

However, methanol has a lower energy density relative to conventional marine fuel oils. This necessitates larger onboard fuel tanks to store an equivalent amount of energy – making methanol a tough choice for smaller vessels that need to keep their weight down.

This conundrum has inspired maritime methanol advocates SRC Group and Green Marine to devise a new type of fuel tank to address these weight- and space-related concerns. The Methanol Superstorage tank is designed for scalability of size and a varied range of vessel types, targeting both newbuilds and retrofits. “From a technical perspective, there are no specific limits regarding dimensions or capacity – the tank can be as large as required,” Alex Vainokivi, innovation manager at SRC Group, tells Ship & Boat International. “We are discussing some Methanol Superstorage tanks that offer 2m3 and others that offer 700m3.”

This flexibility, adds Green Marine MD Chris Chatterton, makes the tank concept “a game changer on small vessels, where space is even more critical for lower-energy-content alternative fuels”.

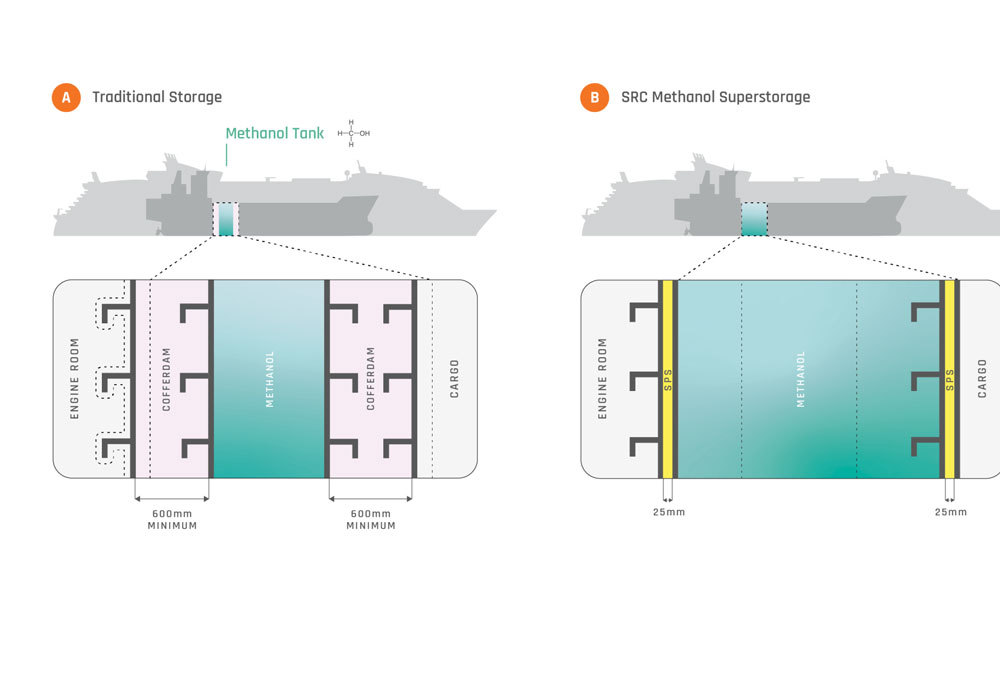

So, how does one go about saving space and weight while guaranteeing a sufficient volume of methanol for trips out to sea? The partners say they have achieved this by replacing the traditional cofferdams that separate gas tank walls with the sandwich plate system (SPS) developed by SPS Technology.

As previously covered in Ship & Boat International, the SPS comprises two metal plates, bonded together with a solid polyurethane elastomer core. The system’s reported advantages include reduced weight and superior impact resistance, and so the SPS has been used to repair damaged vessel decks, bulkheads, side shells, bow sections and mooring points. The SPS can also reinforce existing structures (including helidecks, control rooms and tanks) aboard vessels and offshore platforms, while its elastomer core helps to dampen noise and vibrations.

Vainokivi and Chatterton believe that, by applying the SPS to the Methanol Superstorage tank and subsequently removing all cofferdams, the unit could boost shipboard methanol tank volumes by 85%. Vainokivi says: “It takes around 2.5 times the methanol to achieve energy efficiency equivalent to HFO. The key difference with Methanol Superstorage is that the SPS does the same job as a conventional tank wall; we don’t need the cofferdam around the internal tank. Cofferdams also require inspection and maintenance, which tanks constructed using the SPS do not.”

The Methanol Superstorage solution has swapped traditional cofferdams for SPS’ sandwich-plate system, to increase tank volume

Vainokivi also points out that the steel-polymer-steel barrier used in the SPS has been approved by IACS members for permanent repairs “for over two decades”. Additionally, class lab tests of the SPS have highlighted another interesting property of the system’s polymer core: it boasts high levels of chemical resistance, making it suitable for long-term exposure to methanol.

The marine sector’s growing interest in alt-fuel adoption has prompted calls for revamped crew training regimes, to ensure that personnel handle these new ‘green’ solutions safely. Vainokivi remarks: “Our solution does not require any additional, special training – but, as a company with a focus on vessel refits, SRC Group is not only looking at the tank but at the whole fuel-handling and logistics set-up. This is one of the reasons why we teamed up with Green Marine, whose services to owners include project supervision, technical management and training for crew.”

Green Marine’s Chatterton adds: “While no special training is formally required, class, Green Marine and the International Bunker Industry Association [IBIA] recommend crew are trained in the safe handling of methanol as a low flash-point fuel.” As this factor could spell increased risk of ignition from sparks, heat or static electricity, there is an obvious need for enhanced fire safety training when dealing with the chemical.

Class society Lloyd’s Register (LR) has granted Approval in Principle (AiP) status to the Methanol Superstorage concept, in accordance with LR’s Rules and Regulations for the Classification of Ships using Gases or other Low-flashpoint Fuels (July 2022), as well as Appendix LR1 – Requirements for Ships Using Methyl Alcohol (Methanol) or Ethyl Alcohol. “Based on our discussions with owners, we expect the first retrofits to be initiated in 2025,” Vainokivi predicts. “In 2022, methanol accounted for 3% of the order book; by 2030, this could be close to 20%, representing up to 1,200 vessels. We’ve recorded lots of interest from owners and yards for vessels of under 100m in length, including tugs, yachts, support vessels for wind farms and more.”