The Naval Architect: March 2020

The application of biomimetics to coatings technologies and hull surfaces has been an area of interest to maritime for some years. In the early 2000’s, the US Navy-funded research at the University of Florida led to the development of an artificial technology named Sharklet. But the challenges of manufacturing and applying it to a scale suitable for a ship’s hull have hitherto not been solved.

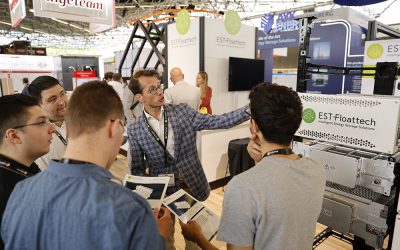

However, a Horizon 2020-backed initiative is taking a quite different approach to the development of biomimetic hydrophobic surfaces. Launched in January 2019, the three-year MultiFlex project is a consortium of laser specialists, the Photonics Private Public Partnership, that has joined forces with the vision of making fast metal processing using lasers a reality.

In February this year, MultiFlex announced that it was harnessing new advances in photonics to develop a high-power (1kW) ‘dot matrix’ ultrashort pulsed (USP) laser system, said to be the first of its kind in the world.

The system is capable of carving flow-optimised metal or plastic surfaces that imitates the microscopic ‘spike’ structures of shark skin, creating a rough surface that reduces drag and inhibits the growth of micro-organisms.

According to MultiFlex’s coordinator, Dr. Johannes Finger, the idea of applying such technology to hull surfaces began with an earlier project for an undisclosed coatings manufacturer. “We had an industry partner that had developed a silicon-based antifouling solution. We were then able to improve upon it by pre-structuring the surface the coating is applied to,” Finger explains.

“Our industry partner said the results were very promising and asked if we could upscale it for larger parts… The laser structuring processes when you use these kinds of lasers are extremely precise and have the benefit of not giving much heat input into the surface, but the downside is that they are very, very slow.”

To the naked eye Finger says the laser-etched metal looks almost as if it has been sandblasted, but the shark skin effect is at a microscopic level. Although the basic principle is similar to that of the Sharklet structure, patent restrictions meant that another structure with a different geometry was used, which has shown promising results.

“The idea we are working on now is to build the enabling technologies that can be used for production-scale, large area structuring. Once we’ve achieved this we want to go back and make these things for real-world applications.”

A ‘dot matrix’ laser being developed applies a similar principle to the traditional dot matrix printer, with a movable head that emits concentrated pulses of energy to ablate the materials. The ultimate aim of the project is to create a processing head using a grid of 64 laser ‘beamlets’ of 25µm diameter, each of which can be individually tuned and positioned for optimum results.

However, the real significance of the project resides less in its precision than in the speeding-up of a process that can take weeks. “Our system will ablate more than 150mm3 in one minute, therefore making it hundreds of times faster than existing technologies.”

Beyond hull surfaces, Finger foresees the technology may have wider, and more immediate applications outside of the maritime industry. These include things such as printing and embossing tools, where the faster, more precise and economical production possible with the MultiFlex system could have significant benefits.

Another area is the automotive industry, which already makes extensive use of lasers, where it could be applied to micro-structuring for interior lighting, instrument clusters or haptic structures.

“We are now entering the intense project phase where we’ll see whether everything we thought is correct, or if there are any problems we didn’t foresee. At the end of 2021 we’ll have finished everything.”

For further information visit: https://multiflex-project.eu/