Japan’s offshore wind farm sector is gaining momentum as part of the country’s push for carbon neutrality by 2050. The country aims to install 10GW of offshore wind capacity by 2030, and as much as 30-40GW by 2040, with a focus on both fixed-bottom and floating turbines – the latter technology being particularly important due to the country’s deep coastal waters.

There have been a few short-term setbacks over the past five years, mainly related to supply chain glitches, inflation and technical challenges. However, Japan’s potential for an offshore wind infrastructure exceeding 9,000TWh per year has attracted OEMs, suppliers, service providers – and, of course, boat operator and builders. For example, this year saw Japanese operator Tokyo Kisen Co take delivery of the first of two bespoke aluminium crew transfer vessel (CTV) catamarans. The first in the new TK-27 class, designed exclusively for Tokyo Kisen by Australian naval architect Incat Crowther, completed its sea trials in late 2024, before being delivered to the operator in April 2025.

This vessel and her in-build sister have been constructed by Cheoy Lee in Hong Kong and classed domestically by ClassNK, with Tokyo Kisen also providing input into the duo’s design, to ensure that the boats were suited to their working environments off the coast of Japan – and to meet recently revamped but stringent local rules.

Incat Crowther elaborates: “The design was developed in compliance with ClassNK rules for High-Speed Craft, while also incorporating its newly introduced rule addition: Part O (12) – Wind Farm Support Vessels, which had recently been appended to the Rules for the Survey and Construction of Steel Ships. This led to conflicts between the High-Speed Craft and Steel Ship rules, with the latter being naturally unsuitable for a 27m aluminium catamaran.”

While resolving these conflicts proved somewhat challenging – not least with ClassNK being “relatively new to the CTV industry”, Incat Crowther tells The Naval Architect – the debut cat has become the first vessel to adopt this new amendment, thereby opening the door for further builds of this type.

The design of the cats has also been “future-proofed”, Incat Crowther explains, in terms of both occupancy and propulsion. For example, while each TK-27 cat will begin its working life carrying 12 turbine technicians, it will retain the flexibility to boost this number to 24 “as Japan’s regulatory framework evolves” and CTVs become more commonplace – and as the country’s network of turbines expands, the designer points out. Similarly, both cats have been prepped for future fuels. While each currently employs twin Yanmar 12AYM-WET main diesel engines, rated 1,220kW apiece and ensuring a top speed of 28knots, it will be possible to upgrade the boats to dual-fuel or even all-electric/pure-biofuel operations as these technologies gain pace. The Yanmar engines are combined with a controllable-pitch propeller (CPP) system supplied by Servogear.

Incat Crowther has designed nearly 50 CTVs over 25m, many of which operate in Europe’s offshore wind farm sector. While Japan’s offshore wind industry presents unique challenges, the designer notes that adapting vessels to Japanese weather and wave conditions was a manageable transition. “The conditions around the Japanese coastline were no more challenging than those typically encountered in European offshore wind farms,” the group reveals.

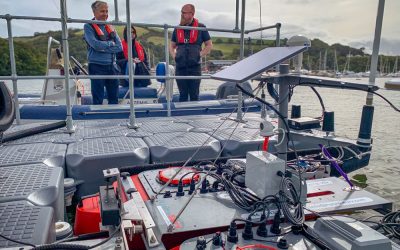

Each TK-27 cat offers a 45m2 useable foredeck cargo area and 18m2 of aft deck, both strengthened to accommodate a combined maximum payload of 35tonnes, and the superstructure is resiliently mounted for lower noise and vibrations. The TK-27 twins also incorporate Incat Crowther’s Resilent Bow Technology, developed to minimise impact loads at the wind turbine boat landings and to reduce onboard accelerations. Incat Crowther says: “This, combined with the high bollard pull, will provide a transfer wave height in excess of 2m” – thus extending the CTVs’ operational windows.

Each cat’s main deck houses a large mess area, two bathrooms and an internal storage and personnel change area. The upper deck features the elevated wheelhouse, a private mess and a pantry, while the lower decks offer two twin cabins, a workshop space and a utility room. Other onboard capacities include tankage for 25,400litres of fuel oil, 2,500litres of fresh water and 2,000litres of sullage.

See The Naval Architect June 2025 for the full technical particulars