Capt. Dr. Seyedvahid Vakili, research associate, World Maritime University svv@wmu.se

Professor Dr. Aykut I. Ölçer, director of research, World Maritime University aio@wmu.se

Shipyards are usually placed near to cities and act as an economic driver for their development, while cities provide the necessary resources and infrastructure for shipyards. However, shipbuilding is a polluting industry that threatens the sustainability of cities. There is a lack of research looking at the interconnectedness of shipbuilding and cities, and less attention is paid to the sustainability of the shipbuilding industry. Shipbuilding produces waste, pollutants and air emissions that each have negative impacts on human health and the environment. To minimise such negative impacts it is crucial that shipyards promote their sustainability and follow the “sustainable concept” within their portfolio.

A shipyard is an industrial production facility that uses materials and energy to design, build, repair, maintain and decommission ships. Shipbuilding processes include cutting, bending, welding, sandblasting, painting and coating, which are complex, energy-intensive and have significant environmental and climate impacts. The industry accounts for about 4-8% of the life cycle carbon dioxide emissions of ships and 29% of carbon monoxide emissions. There are also emissions of volatile organic compounds (VOCs) that form tropospheric ozone, which is dangerous to humans and nature.

Shipping is becoming a “green”, “zero-emission” industry, in line with the commitments made in the IMO’s initial strategy to reduce greenhouse gas (GHG) emissions from ships. International regulations currently focus on the operational phase of the industry, which has the largest climate impact during the life cycle of a ship. As the environmental impact of this phase decreases, the contribution of the shipbuilding industry to climate change is expected to increase. It is therefore important to reduce the negative impact of energy consumption during shipbuilding. With a view to reducing air emissions from the operational phase, considering the emissions from shipyards during the stages of construction, maintenance, and disposal is crucial in effectively mitigating air emissions across the entire life cycle of ships. These emissions can account for over 50% of the total emissions produced throughout a ship’s life cycle. For example, a battery-powered ferry using electricity from the Norwegian grid has a higher carbon footprint throughout its lifecycle than during its operational period. Given the above, one can imagine the future, with a complete “cradle to grave” approach, covering the entire life cycle of the ship from the construction phase to the scrapping, for reducing CO2 emissions in the maritime industry.

In light of the above there is no comprehensive approach to reducing CO2 emissions from shipbuilding and to managing air emissions from ships throughout their life cycle (construction, operation and dismantling), and all IMO regulations are focused on the operational phase of ships. However, if the aim is to promote “green”, “zero-emission” and “sustainable shipping” in order to reduce air emissions from shipping, the “cradle to grave” approach to reducing air emissions from shipbuilding must be taken into account. In order to promote green shipping in the context of the life cycle approach, the World Maritime University (WMU) conducted research and established new definitions and taxonomy for a sustainable shipyard. The research divided the sustainable shipyard into two categories, clean and green shipyards, and in order to promote green shipping from a life cycle perspective, the study developed a holistic, systematic and transdisciplinary approach to energy management.

Clean shipyard

Shipyard activities have negative impacts on water, land and soil. A clean shipyard applies a systematic approach and complies with international, regional and local regulations to assess environmental aspects and prevent, reduce and minimise the ecological impact of its activities on land, soil and water. The key elements of a clean shipyard in the shipbuilding industry are three Rs, namely:

- Reduction of demand in resources,

- Recycling, and

- Reuse of material and resources.

Taking into account the sustainability of materials, the life cycle aspects of the selected materials and their dismantling challenges at the early stage of the ship design are key factors to promote a clean shipyard. The main objective of the clean shipyard is to eliminate waste in the production and support processes at the yards. If the waste is generated, these wastes should meet the requirements of environmental friendliness, recyclability and reusability. Based on this approach, a clean yard can be defined as follows: “A yard is considered to be absolutely clean when all production and supporting processes in the manufacture of a ship have zero environmental impact.” However, in order to achieve a clean shipyard, the responsible entities in the shipyard need to design, develop and implement some management frameworks, such as waste management, water management, air and underwater noise management, sweat management, waste-to-energy management, industrial symbiosis and circular economy frameworks.

Green shipyard

Consumed energy in shipyards can be divided into three branches serving the production process, support process, and intermediate process (such as transportation in the shipyard). Due to the energy-intensive nature of shipyards, the level of energy consumed plays a crucial role in promoting shipyard sustainability. With this view, highlighting the role of energy and the importance of reducing/eliminating polluting emissions can raise awareness among society, shipyard managers and policy makers. Green shipyards should undeniably strive to minimise energy consumption and related pollutant emissions as well as emissions of non-energy related resources, such as volatile organic compounds from coatings and paints and dust from surface treatment, cutting and welding. For this reason, green shipyards should consist of three main principles in the energy chain, namely production, consumption and conservation.

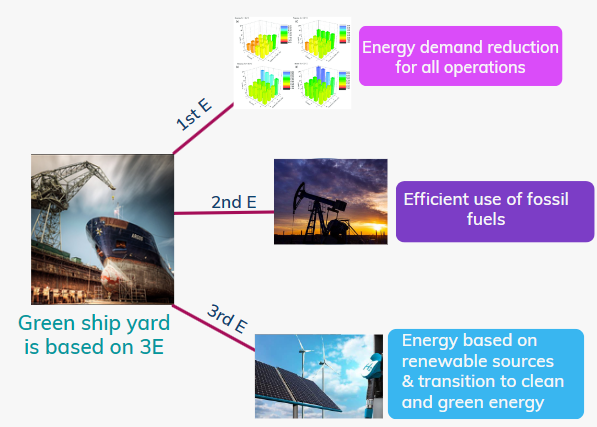

The key element of the 3E approach, i.e. Trias Energetica or based on Energy, Environment and Economy (see Figure 1), not only reduces air emissions but also contributes to the design and implementation of a transdisciplinary EnMF (Energy Management Framework) to promote socio-economic criteria for sustainable development. To achieve such green shipyard strategies, energy sources must be used as efficiently and sustainably as possible to minimise air emissions and improve air quality through a near-zero or zero-emission pathway. Based on the 3E criterion, the definition of a green shipyard could be the following: “A shipyard is considered to be absolutely green when all production and supporting processes in the manufacture of a ship have zero air emissions.” In order to achieve a green shipyard, the yard’s DMs (decision makers) must design, develop and implement a holistic energy management framework that includes measures and tools such as energy production, energy performance and auditing, energy conservation, energy monitoring systems, air pollution monitoring systems, alternative clean fuels and smart micro grids.

On the basis of the above analysis, it can be concluded that improving the operational efficiency of the yard, e.g. through lean manufacturing, could contribute significantly to promoting clean and green yards. In addition, each single operation in individual clean and green shipyards should be carried out efficiently in order to increase competitiveness and to develop the economy. Complying with local, national, regional and international standards and adopting best practices is also a task for clean and green shipyards to be prepared for unforeseen consequences of climate change and related negative impacts. However, the process of preparing a scenario to respond to such consequences and related impacts should evaluate climate resilience, take into account the legal framework and analyse the quality and risk of the system to propose appropriate management policies and solutions. A sustainable shipyard could therefore be defined as follows: “A shipyard is considered sustainable when all production and supporting processes in the manufacture of a ship have both zero environmental impact (clean shipyard) and zero air emissions (green shipyard).”

3E criteria for the clean and green shipyard

Energy management framework in a green shipyard

To promote sustainability, economic and ecological values must be combined to achieve a win-win result. This needs improving in resource and energy efficiency and developing innovative solutions such as management frameworks and clean and renewable technologies. To tackle climate change, which is the priority of this century, as well as to promote human health, considering a holistic approach in sustainable energy production and energy policy are crucial and by referring to the ramifications of climate change can justify having such a policy in the maritime energy sector. An example of such an energy policy at the regional level is the recently agreed EU Green Deal, in which it is based on four pillars: carbon pricing (marine traffic will be considered in ETS), sustainable investment, industrial policy, and transition.

The EU strives to address pollution from heavy industries such as shipbuilding by adopting related policies consistent with climate change, energy, and circular economy policies and by focusing on energy measures. At the industrial level, the primary concern of industrial managers is economic prosperity, competitiveness, profit, safety, and stability of their business. Due to increasing awareness about environmental aspects, stringent environmental regulations, and Corporate Social Responsibility (CSR), businesses pay increasing attention to the environmental elements and strive to reduce their negative impacts by managing energy consumption. To achieve efficient-energy use, every shipyard needs to have a long-term energy strategy and fulfil an energy management programme. It is clear that only a holistic and integrated approach to renewable, clean and zero-emission energies can mitigate air emissions – it is considered as a sagacious strategy towards the clean and green processes in shipyards. Alternatively, to fulfil zero air emissions from the shipping industry, it should take into account the role of lifecycle analysis in the mitigation of emissions. Relating to the EnMF of shipyards, it could be utilised to determine the procedures aiming to have a long-term strategy associated with energy production, consumption, and conservation. The EnMS (Energy Management System) is considered as the measures and tools, which could be employed for implementing the procedures to achieve the strategic goals.

The framework provides the shipyards’ managers with an opportunity to make a simple and rational decision in a complicated situation. However, in order to support the EnMF in the shipyards, the related EnMS must be appropriately adopted in the shipyards’ organisations. The framework, by considering a holistic and interdisciplinary approach, could be applied to break the silos and provide depth (knowledge extent), breadth (knowledge criteria), and synthesis (integrating different knowledge/perspective into uniform knowledge/experience) to optimise the decision of DMs. Employing the framework leads to mitigating industrial air pollutants and GHG emissions from shipyards. This type of approach promotes the “Green Shipyard” concept and supports sustainable shipping. In addition, the framework, with taking into account the life cycle analysis of the procedures in shipyards, would support the zero-emission shipbuilding industry, green products, and mitigation of emissions.

To reach the EU’s ambitious goal (climate neutral continent by 2050), developing, implementing, and complying with EnMF within shipyards can be part of industrial policy in alignment with the EU Green Deal for decarbonisation of transportation. Moreover, applying the EnMS leads to the improvement of energy efficiency and air quality and a reduction of air emissions within the shipyards which makes it a cost-effective measure in relation to the Emission Trading Scheme (ETS). Meanwhile, shifting to green technologies and using renewable sources of energy to power the shipyards is a sustainable investment that fosters job creation and promotes innovation, as well as assisting in the transition process and export of the EU Green Deal.

EnMF can be designed and developed for different sized shipyards and other industrial sectors. Shipyard size, location, and type of operations play an important role in selecting priorities for improving energy efficiency in shipyards. As flexibility is one of the key features of the framework and as there is no “one-size-fits-all” approach to improve energy efficiency, the framework could be adapted based on the shipyards’ portfolio and DMs’ priorities, as well as trading-off between issues to adjust the framework to any size and type of shipyard. The final EnMF and EnMS for each shipyard could be designed and developed by comparing the present case and alternatives concerning the defined criteria. Multi-Criteria Decision-Making (MCDM) methods could be used to identify the best alternatives to support a Decision Support System (DSS) and assist the DMs in making more rational and optimised decisions in multi-criteria and fuzzy areas. Moreover, the design, development, and implementation of such a holistic framework could raise policymakers’ awareness to adopt policies by considering energy management to enhance energy efficiency potential and create a movement to meet the zero-emission goal in the life cycle of ships.

An energy management framework for shipbuilding, an energy-intensive industry, can improve economic competitiveness and benefits through reduced energy costs and enhanced industrial capacity in the ETS, as well as reduce socio-economic costs. It also enables capacity building and staff training in shipyards and beyond. This approach enhances the reputation of the yard in the competitive market and can act as a brand for the yard and give the yard a better bargaining position to access the required financing.

Shifting to green technologies and using renewable sources of energy to power the shipyards can be a sustainable investment that fosters job creation and promotes innovation

Implementation of the framework

The proposed energy management framework has been implemented at selected yards, each of which has a different size and portfolio. The results show that the implementation of the framework can lead to socio-economic and environmental benefits and promote the sustainability of the shipyard cities. In addition, the results of the yard surveys show that large yards in developed countries are more sustainable than small and medium-sized yards in developing and less developed countries. In terms of reducing air emissions, large yards in developed countries had short-, medium- and long-term energy options, taking into account the priorities of the different stakeholders, that could make them energy hubs by using renewable energy and producing green hydrogen and ammonia. They also introduced sustainable business models and insisted on the long-term survival of the yard. However, small and medium-sized shipyards in developing or less developed countries focused more on the economic pillars of the business model to maximise profits for shareholders as the traditional stakeholder.

Taking the above into consideration, the potential use of solar cells, wind turbines and generators in stand-alone and grid-connected hybrid systems has been assessed for a large European shipyard. As a stand-alone system, a solar PV system yielded a levelised cost of electricity (LCOE) of 0.053($/kWh), an internal rate of return (IRR) of 11% and a discounted payback period of 6.2 years. As a grid-connected hybrid system, a solar PV, wind turbine and diesel generator configuration yielded an LCOE of 0.109($/kWh), an IRR of 28.9% and a discounted payback period of 3.53 years. The sensitivity analysis showed that cases with a configuration of generators were more sensitive to the diesel price than to the cost of renewable energy technologies.