Ulstein Verft has delivered Windea Clausius, the second in Bernhard Schulte Offshore’s new series of commissioning service operation vessels (CSOVs), writes Patrik Wheater. Windea Clausius and her sister Windea Curie, delivered in June, form part of an extensive newbuild programme that began in 2023. Hulls three and four are on schedule for delivery next year and will also enter service under the Windea Offshore joint venture, established to provide integrated logistics and operations support to wind farm developers in the North Sea and Baltic.

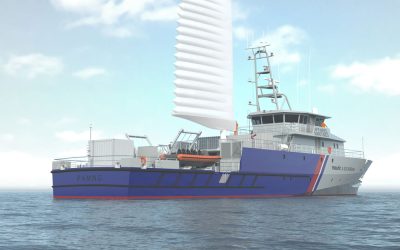

Built to Ulstein’s SX222 platform, unveiled in early 2021, the 2,200dwt Windea Clausius combines a methanol-ready hybrid diesel-electric propulsion plant with Ulstein’s hallmark TWIN X-STERN design, which allows the vessel to operate either bow- or stern-first. Ulstein says the novel hullform improves operability, lowers energy use and enhances comfort by reducing slamming and spray loads when holding position. The TWIN X-STERN – which evolved from Ulstein’s earlier X-STERN family introduced in 2015, and leverages on the success of its X-BOW design from 2004 – is awash with hydrodynamic refinements that include optimised propeller inflow to reduce underwater noise and vibration.

Speaking in 2021, Kolbjørn Moldskred, sales manager at Ulstein Design & Solutions, said: “It’s a completely different experience to be on board. It’s built to operate in strong currents and is less limited by weather conditions. TWIN X-STERN is in the same family as our other two revolutionary hulls, X-BOW and X-STERN, and provides similar benefits, just in a different set-up optimised for the offshore wind segment.”

With an overall length of 89.6m, a 19.2m beam and a draught of 5.9m, Windea Clausius’ hull was built at the Crist Shipyard before being towed to Ulstein Verft in Norway for the final phase, which included outfitting, paint work, electrical installation, equipment integration, commissioning and sea trial. The vessel is built for a service speed of about 10knots with propulsion provided by a Kongsberg Maritime package that integrates two main US 205 azimuth propellers fore and aft with a K-Power DC Hybrid solution, K-Chief EMS/IAS and K-Line control systems for smart energy management, fuel efficiency and optimal performance in dynamic positioning (DP) operations.

Electrical power to these and other consumers is through a hybrid battery-propulsion system, supplied by Everllence, which features a trio of methanol-ready MAN 175D-MEV (variable-speed) gensets, each rated 2.2MW and equipped with an integrated MAN closed-loop selective catalytic reduction (SCR) system to optimise emissions abatement. Indeed, Matthias Müller, Bernhard Schulte Offshore MD, said the engine design “is notable for its flexible use of various fuel grades, including biofuel, and its suitability for dual-fuel methanol retrofits”.

First-in-class Windea Curie represented the first reference for the engine which, when running on methanol, can cut CO2 emissions by up to 95%, NOx by up to 80%, and SOx and particulate matter completely. Complying with IMO Tier III NOₓ-emission standards, the hybrid arrangement is also claimed to deliver up to 10% fuel savings in typical North Sea service and reduce generator operating hours, cutting maintenance costs.

Øyvind Gjerde Kamsvåg, chief designer at Ulstein, said in 2021: “The key advantage of the hull is its ability to stay in position. The secret lies below the waterline. TWIN X-STERN has main propeller units at each end, which provide maximum manoeuvrability. The hull also provides major fuel savings; we have findings from the sister patent X-STERN, which show a reduction in power consumption of up to 60% when manoeuvring stern-first compared to flat transom stern.”

Equipped with a large, height-adjustable, centrally located walk-to-work gangway and elevator tower for personnel and cargo transfers, the vessel includes a 3D motion-compensated crane for offshore lifts of up to 5tonnes. Onboard logistics are optimised with spacious storage areas and stepless access to offshore installations.

While the hull’s symmetry and twin-ended propulsion allow the ship to weather-vane naturally, maintaining heading with minimal thrust and energy demand, the bridge layout follows Ulstein’s Insight Bridge concept, combining navigation, DP, crane and gangway operations in an ergonomic, 360° workspace that improves situational awareness during complex offshore manoeuvres.