Having successfully weathered the effects of the pandemic, the Italian-based shipyard group is going from strength to strength

Unlike some other regional yards, the Palumbo Group did not experience any significant impacts as a result of the Covid-19 pandemic, neither suffering a major absence of workers due to illness nor any significant disruption of planned activities.

Nevertheless, in 2022 the group reported even higher occupancy rates and an increase in the number of standard overhaul projects compared to previous years. Luka Hrboka, group head of sales, says, “One major trend was the fact that we were involved in far more scrubber and BWTS installations to meet environmental regulations. We also noticed an increase in the number of enquiries for large refit projects and a renewed interest in conversions.”

Palumbo’s Naples shipyard has handled a wide range of project types over the past year

Having enjoyed a very positive 2022, Palumbo has started 2023 in a similar vein. Hrboka says, “We have continued to see the excellent trends that ended 2022 with high occupancy rates and a large number of enquiries for standard overhaul works and refits, as well as conversions, all of which is highly encouraging.”

Two major projects that were started last year, a refit of the super yacht Prince Abdulaziz and the conversion of the ro-pax California Star 2, will continue in 2023, while the first half of the year will also see Palumbo group yards tackle some significant projects for MSC Cruise and the US Navy.

Passenger ship refits have been a feature of the workload at Palumbo’s Viktor Lenac shipyard in Croatia

Hrboka adds, “we are very optimistic for 2023, and the foundations have been laid for this success by our high level of workmanship quality, reliability and flexibility. We are currently working on several complex projects, and each of our four ship repair yards, in Malta, Rijeka, Messina and Naples, has at least one demanding project underway.”

There is furthermore no letup in demand for BWTS and scrubber installations. Since Palumbo performed its first BWTS retrofit installation in 2015, the group has completed around 100 projects of this type so far. According to Hrboka, “We are proud to say that we have fully mastered scrubber and ballast water treatment system retrofitting. The expertise gained in these projects performed at Palumbo Group yards places us in an elite group of the world’s top shipyards able to deliver complex BWTS retrofit work, a fact recognised by Wärtsilä when it signed signed a cooperation agreement with us in 2017.”

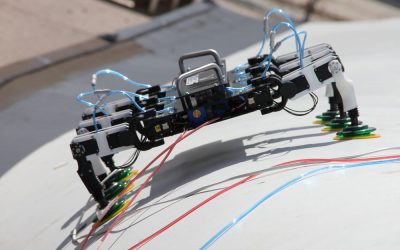

Also high on the Palumbo group agenda is the implementation of environmentally sound technologies within its shipyards. The company has in recent times implemented ultra high-pressure water blasting as an alternative to grit blasting and continues to invest in purchasing new equipment and training its staff in the use of this technology. “Our clients are satisfied that they have such an environmentally friendly option, but in addition, it also means that they will save money because they will not have the high costs associated with the disposal of waste material,” Hrboka said.