Metalock Brasil diversifies to perform cell guide repairs

Metalock Brasil has been expanding its operations through the deployment of riding teams to carry out complex repairs on the cell guides of container ships. These operations were performed while the vessels were in transit, at the request of a leading European shipowner.

Cell guides are vertical steel structures that extend from the ship’s holds to the deck, playing a critical role in keeping containers properly aligned and secure during transport. Damage or wear to these structures can significantly limit a vessel’s cargo capacity, posing both operational and logistical risks.

Given that container ships make very brief stops at ports, making traditional alongside maintenance difficult, Metalock Brasil has been executing these repairs while the vessels are at sea. The dedicated riding teams comprise welding and platework specialists who operate simultaneously in multiple holds, using scaffolding systems that often exceed the height of seven-story buildings.

In the first half of 2025 alone, Metalock says its teams carried out onboard cell guide repairs while vessels were trading between Santos and Rio Grande, Rio de Janeiro and Santos, and Santos and Santo Antônio in Chile.

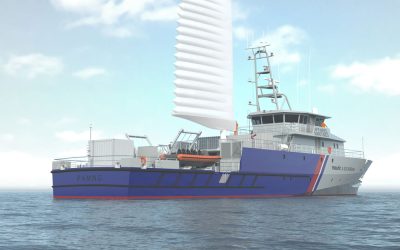

Karpowership’s Kinetics business division has contracted Seatrium to convert an LNG carrier into an FSRU named ‘LNGT Turkiye’

Seatrium secures FSRU conversion contract

Singapore-based Seatrium Limited has been awarded a floating storage regasification unit (FSRU) conversion contract by Karpowership’s Kinetics business division. Scheduled to commence in Q3 2025, the project involves the conversion of an LNG carrier into an FSRU named LNGT Turkiye. The scope of work includes the installation of a regasification module and a spread-mooring system, and integration of key supporting systems such as cargo-handling, offloading, utility, electrical and automation systems.

Currently, two more FSRU conversion projects for Kinetics are in progress at the Seatrium yard, with deliveries scheduled later this year and in Q1 2026.

Hafnia drydocks 13 vessels in six-month period

Tanker operator Hafnia has completed the drydocking of 13 of its vessels over the first half of 2025, undertaking various repairs, special surveys and upgrade works. The vessels concerned were Hafnia Amber, Hafnia Falcon, Hafnia Almandine, Hafnia Valentino, Hafnia Viridian, Hafnia Nordica, Hafnia Andesine, Hafnia Bering, Hafnia Aventurine, Hafnia Ametrine, Hafnia Aquamarine, Hafnia Amethyst, and Hafnia Aronaldo. The vessels underwent Special Renewal Surveys in collaboration with classification societies, including ABS, DNV and Lloyd’s Register. For tankers approaching their 15th year of service, CAP Hull and Machinery Surveys were also conducted.

All of the chemical tankers received a full or partial recoating of their cargo oil tanks with Advanced Polymer Coatings’ MarineLine systems, and were upgraded with new stainless steel common, nitrogen and tank washing lines, with a dehumidifier for tank ventilation and the installation of an extra fixed tank washing machine. The vessels also benefitted from the application of high-performance silicone-based hull coatings to help ensure compliance with IMO’s EEXI and CII measures, while other work included propeller enhancements, with graphene coatings, and the installation of energy saving Propeller Boss Cap Fin devices. Additionally, Alfa Laval BWTS units were installed and steam heating coil systems repairs carried out.

A further seven vessels are scheduled to undergo similar drydockings over the next few months. These include Hafnia Axinite, Hafnia Ammolite, Hafnia Azurite, Hafnia Violette, Hafnia Australia, Hafnia Africa and Hafnia Magellan.